Home Newsletters

General News

High Temp Lubrication

SurTec Purchases Italtechno

SurTec acquires chemical business from Italtecno in Italy

Chemical business of the Italian specialist for aluminium alloys, now part of the SurTec Group

Bensheim, 04.03.2021. SurTec, specialist for surface treatment, acquired the chemical business of Italtecno in Italy, a company based in Modena. Italtecno specialises in the Research and Development, as well as the distribution of chemical specialities for surface treatment for aluminium alloys and steel. The product range includes chemical products for the architectural, automotive and aerospace industries as well as for decorative, mechanical and other industrial components.

SurTec and Italtecno have been working together in the field of Metal Pre-treatment in Italy for many years. SurTec will distribute Italtecno’s products for the aluminium industry, which are very well established in the market, worldwide and further expand the business.

“We are pleased that Italtecno’s chemical business is getting a long-term future at SurTec,” explains Dr. Walter Dalla Barba, Managing Director Italtecno. “In view of a growth-oriented strategy, the owners have decided to manage the succession of Italtecno’s chemical business through the acquisition by a long-term strategic partner.”

“Italtecno has already been our partner for Metal Pre-treatment in Italy for many years and is familiar with our company philosophy, which aims to harmonise entrepreneurial processes with the needs and requirements of society and the environment,” adds Dr. Karsten Grünke, CEO of SurTec. “By acquiring Italtecno’s chemical business, we can strengthen our position in the important Italian market even more, as we will be able to offer our entire product portfolio, including electroplating products, directly there in the future.”

Italtecno’s global customers will additionally benefit from SurTec’s worldwide distribution network and technical expertise.

Links

Anodising News

Australia's Most Versitile Acid Recovery

De-smutting

The de-smutting process on an aluminium anodising line is the act of removing excess alloyed metals from the surface of aluminium after etching or brightening. It is required in the anodising process after caustic etching or acid bright dipping. After these etching processes, the surface of the aluminium looks cloudy which is commonly called smut, hence the process step: de-smutting.

AUSCHEM’s proprietary products developed for de-smutting are: Desmut XF & Desmut AW (new improved formula)

Desmut AW characteristics:

. Used at ambient temperature

. Excellent performance when used for matt caustic etching or acid brightening

. Shortened processing time

. Excellent performance on alloys used in bright dipping

. Contains iron salts rather than fluoride, thus avoiding fluoride ions being dragged into the anodising tanks circumventing any chance of pitting.

please contact us at sales@auschem.com.au for further information.

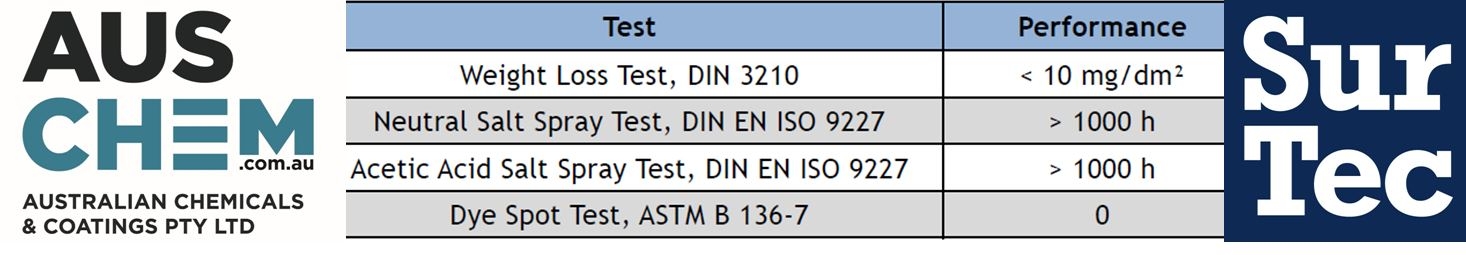

SurTec 350

Surtec 350 is an innovative cold seal for aluminium anodising, with the benefit of being nickel free. Combing with a hot seal/rinse the issues of crazing (micro cracking) are eliminated at 1/3rd of the standard sealing times.

Removing nickel from the process offers obvious effluent benefits along with the OH&S health advantages. ST 350 also offers improved corrosion resistance over the nickel based cold seals, allowing it to meet and exceed the volume specs for alkaline resistance.

Without any negative impact on crazing and reducing the rolling boil times from 3 to less than 1 min/micron another big advantage is reducing the bottlenecks that invariably occur due to standard seal times at the end of the anodising process. By having these reduced times massive energy savings will be achieved as the need to keep multiple tanks at a rolling boil is eliminated.

please contact us at sales@auschem.com.au for further information.

SurTec 645

SurTec 645 replaces nickel dye pre-seals, effectively reducing bleed without the need for nickel salts.

BENEFITS

This new technology has been developed with mobile phone companies for the safety of their consumers.

please contact us at sales@auschem.com.au for further information.

Electroplating News

Industrial Lubrication

Plastisol News

Powdercoating News

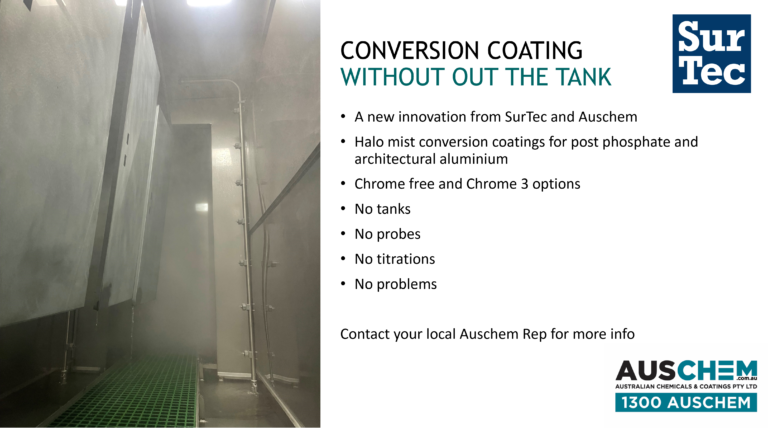

Conversion Coating Without The Tank

Introducing SurTec 643

Chrome-free is becoming the industry standard for the pre-treatment of Aluminium prior to powder coating in the architectural industry. Titanium- and Zirconium-based systems have successfully replaced Chrome(VI) in the majority of the world, but compared to Chrome(VI)-systems, Chrome-free systems are invisible, they have much tighter operation windows and they are quickly moving towards borderline performance in respect to filiform corrosion and paint adhesion, especially in case of ageing or contamination of the bath.

SurTec 643 combines SurTec’s long-term experience in running and operating Chrome-free technologies in regions like France, Middle East or North Africa with the well-founded understanding of our technical community to improve specific characteristics of metal pre-treatment processes. The result is a product, which uses the traditional skeleton of Zirconium and Polymer, but the choice of a brand new polymer in combination with the optimal Zirconium ingredients leads to an innovative and unique product. The coating can comfortably be controlled via the bath and easily measured in the coating. In addition, it shows a significantly improved performance in respect to filiform corrosion and paint adhesion, especially when it comes to contamination and ageing effects. On top, the uniformity of the coating weight along a profile, especially in vertical lines, could be optimized.

To cut it short: SurTec 643 brings comfort and safety to Aluminium coaters to run and control a Chrome-free process.

please contact us at sales@auschem.com.au for further information.

As acid etching remains Australia’s most common pre-powdercoating surface preparation for aluminium finishers, it is important that the most up to date and efficient chemistry developments are a high priority. For volume applicators, Australian Chemicals & Coatings has developed our Alumbrite 21 Series acid etching for extruded, honed and sheet aluminium alloys.

Alumibrite 21 Series comes in various forms specific to requirements for dip tanks, horizontal spray lines and vertical lines. All products in the series have the benefits of much lower consumption than traditional chemistry, reduced operating strength, reduced load on rinse tanks (especially important for closed loop DI systems), reduced risk of chromate poisoning, inhibitors to protect stainless steel tanks and baskets and aluminium precipitation aid to reduce load on waste treatment. Alumibrite 21 Series is specifically designed for optimum probe dosing.

In summary: Alumibrite 21 Series brings efficiency from all angles and is a worthwhile consideration for your plant.

please contact us at sales@auschem.com.au for further information.

SurTec 609GV

For the best multi-metal pre-treatment go no further than SurTec 609GV Zetacoat.SurTec 609GV out performs zinc phosphate in most applications without heat or sludge. Incredibly easy to use promoting excellent protection and adhesion, whether contact time is 30 seconds or 5 mins you will not see delamination

There is no other product on the Australian market with such performance and versatility. This ROHS compliant chemistry is especially robust against flash rusting and is suitable as multi-metal passivation prior to painting steel, aluminium, HDG, EG, zinc and zinc die cast.

please contact us at sales@auschem.com.au for further information.

Alumifix BN

As chromate baths age they can slow down and stop working. Many of our competitors will advise that a very costly bath dump is necessary, however, this may not be the case.

Auschem is the only company in Australia offering an in situ fix.

Alumifix BN was developed to counter the sulphate drag in & extend the bath life of older chromate conversion baths. Particularly where the number of rinse tanks are limited & water flow rates are not removing the sulphate levels in these rinse tanks. Consequently the sulphate ends up in the chromate conversion bath slowly reducing the bath quality.

please contact us at sales@auschem.com.au for further information.

Closed Loop DI

Using a Closed Loop DI system? .Reduce the load on it and dramatically improve time between regenerations with SurTec 650, up to 3 x the run time between regenerations. Along with its bare metal protection benefits it has the longest bath life of any chrome 6 free product on the Australian market, and does not require a bleed.

Chrome 6 is an oxidising anion. The resins in these systems suffer from reduce lifespan in the presences of oxidisers making resin replace (very high cost) more frequent. SurTec 650 does not contain oxidisers or anions means extended lifespan of resin and reduced load on resins.

Remove carcinogenic chrome 6 from your plant whilst improving costs on bath life, consumption, regeneration/waste treatment costs. All this and maintain comparable performance to chrome 6 with an easier to use, non DG, product.

All of the above adds up to large cost savings, short term and long term.

please contact us at sales@auschem.com.au for further information.

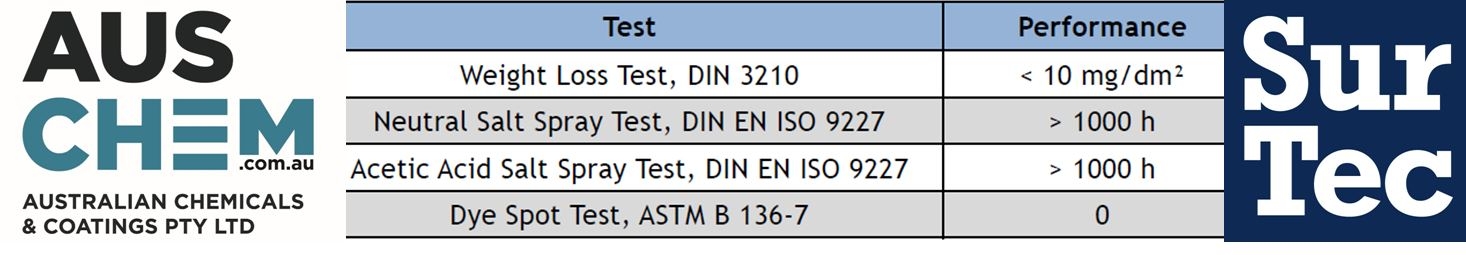

ALuminium Pretreatment Types and Performance Levels

As yellow (gold) chromate is becoming harder and harder to use safely and dispose of waste, it is important to remember that chrome free is not the only choice.

With Surtec’s range of safe, non toxic, ROHS approved chrome III choices it is not essential to go all the way from chrome VI to chrome free. Chrome III offers superior protection, wider coating parameters and serious ease of use benefits. Chrome III has become the chemistry of choice for aerospace bare metal protection, a function that chrome free cannot offer.

please contact us at sales@auschem.com.au for more info on your Qualicoat approved chrome free and chrome III choices.

Alugold SCR

Introducing ALUGOLD SCR, new to SurTec from the Italtechno range. ALUGOLD SCR is a Qualicoat approved non chrome with colour! As seen above.

ALUGOLD SCR is a coloured chrome-free liquid process, based on a perfect balance of inorganic acid salts. In contact with aluminium it reacts to form a coloured passivation layer of metallic complexes particularly suitable for aluminium treatment before powder coating. The product is chrome-free. ALUGOLD SCR may be applied by spray, cascade or dipping.

Australian Chemicals & Coatings are now able to offer to the Australian and New Zealand market a product that has the health benefits of non chrome with the visual benefits of chrome 6.

With SurTec’s acquisition of Italtechno we are now able to combine Italtechno’s aluminium expertise with SurTec’s facilitlies and Australian Chemicals & Coatings local support.

please contact us at sales@auschem.com.au for further information.

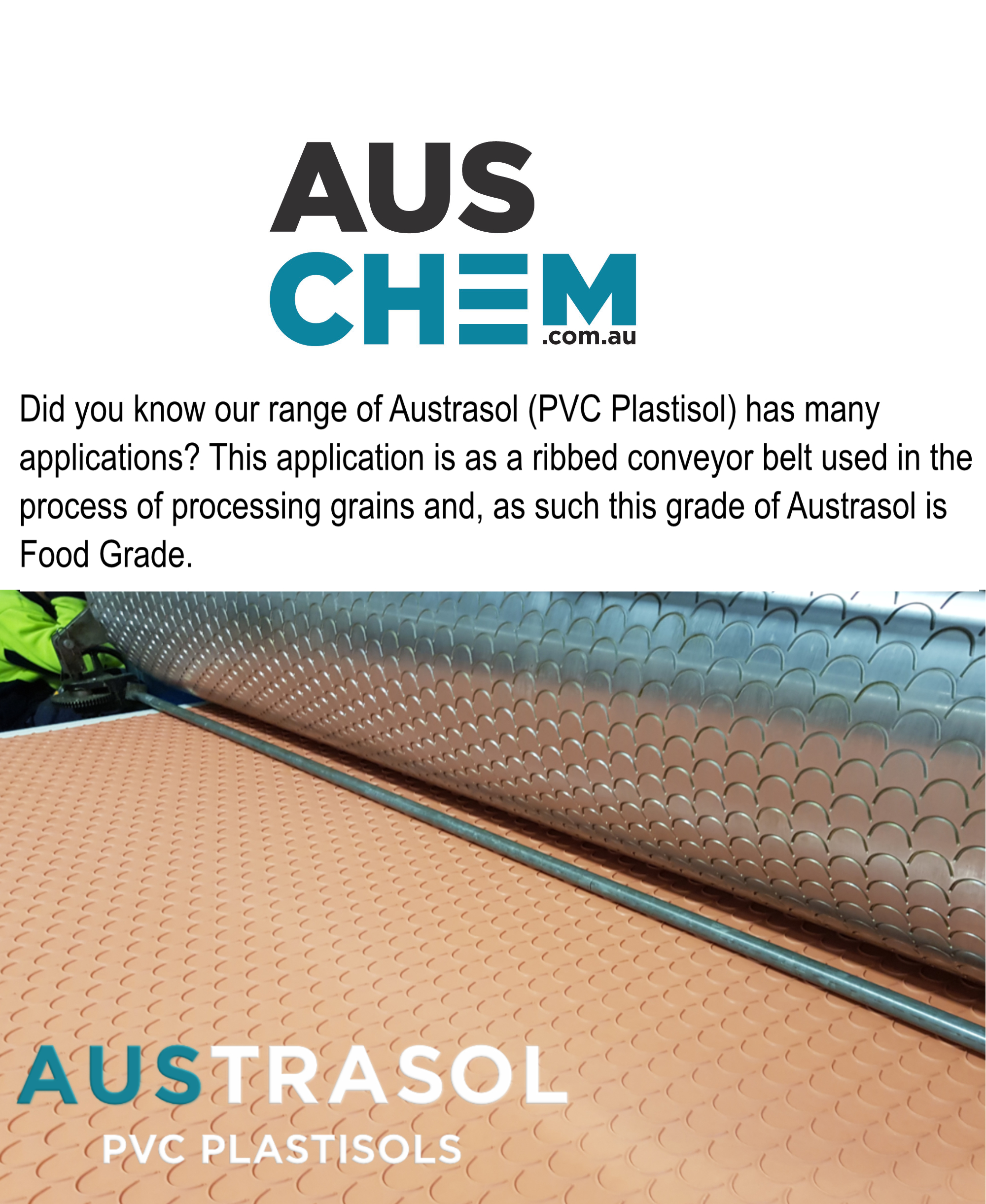

PVC Plastisol

AUSTRASOL PVC PLASTISOL

AUSTRASOL PVC PLASTISOLS

General News

AISF PRESENTATION

Classique Strip E3000

Surtec 680

SurTec 650

High Temp Lubrication

SurTec Purchases Italtechno

SurTec acquires chemical business from Italtecno in Italy

Chemical business of the Italian specialist for aluminium alloys, now part of the SurTec Group

Bensheim, 04.03.2021. SurTec, specialist for surface treatment, acquired the chemical business of Italtecno in Italy, a company based in Modena. Italtecno specialises in the Research and Development, as well as the distribution of chemical specialities for surface treatment for aluminium alloys and steel. The product range includes chemical products for the architectural, automotive and aerospace industries as well as for decorative, mechanical and other industrial components.

SurTec and Italtecno have been working together in the field of Metal Pre-treatment in Italy for many years. SurTec will distribute Italtecno’s products for the aluminium industry, which are very well established in the market, worldwide and further expand the business.

“We are pleased that Italtecno’s chemical business is getting a long-term future at SurTec,” explains Dr. Walter Dalla Barba, Managing Director Italtecno. “In view of a growth-oriented strategy, the owners have decided to manage the succession of Italtecno’s chemical business through the acquisition by a long-term strategic partner.”

“Italtecno has already been our partner for Metal Pre-treatment in Italy for many years and is familiar with our company philosophy, which aims to harmonise entrepreneurial processes with the needs and requirements of society and the environment,” adds Dr. Karsten Grünke, CEO of SurTec. “By acquiring Italtecno’s chemical business, we can strengthen our position in the important Italian market even more, as we will be able to offer our entire product portfolio, including electroplating products, directly there in the future.”

Italtecno’s global customers will additionally benefit from SurTec’s worldwide distribution network and technical expertise.

Links

Anodising News

Australia's Most Versitile Acid Recovery

De-smutting

The de-smutting process on an aluminium anodising line is the act of removing excess alloyed metals from the surface of aluminium after etching or brightening. It is required in the anodising process after caustic etching or acid bright dipping. After these etching processes, the surface of the aluminium looks cloudy which is commonly called smut, hence the process step: de-smutting.

AUSCHEM’s proprietary products developed for de-smutting are: Desmut XF & Desmut AW (new improved formula)

Desmut AW characteristics:- Used at ambient temperature

- Excellent performance when used for matt caustic etching or acid brightening

- Shortened processing time

- Excellent performance on alloys used in bright dipping

- Contains iron salts rather than fluoride, thus avoiding fluoride ions being dragged into the anodising tanks circumventing any chance of pitting.

please contact us at sales@auschem.com.au for further information.

SurTec 350

Surtec 350 is an innovative cold seal for aluminium anodising, with the benefit of being nickel free. Combing with a hot seal/rinse the issues of crazing (micro cracking) are eliminated at 1/3rd of the standard sealing times.

Removing nickel from the process offers obvious effluent benefits along with the OH&S health advantages. ST 350 also offers improved corrosion resistance over the nickel based cold seals, allowing it to meet and exceed the volume specs for alkaline resistance.

Without any negative impact on crazing and reducing the rolling boil times from 3 to less than 1 min/micron another big advantage is reducing the bottlenecks that invariably occur due to standard seal times at the end of the anodising process. By having these reduced times massive energy savings will be achieved as the need to keep multiple tanks at a rolling boil is eliminated.

please contact us at sales@auschem.com.au for further information.

SurTec 645

SurTec 645 replaces nickel dye pre-seals, effectively reducing bleed without the need for nickel salts.

BENEFITS- Nickel free

- Reduced dip time

- Reduced bath temp

This new technology has been developed with mobile phone companies for the safety of their consumers.

please contact us at sales@auschem.com.au for further information.

Electroplating News

Surtec 680

AUSTRASOL PVC PLASTISOLS

Industrial Lubrication

Powder Coating

Classique Strip E3000

Classique Strip ~ Paint Removal

SurTec 650 Corrosion Protection

SURTEC 650 ~ Corrosion Protection

Conversion Coating Without The Tank

Introducing SurTec 643

Chrome-free is becoming the industry standard for the pre-treatment of Aluminium prior to powder coating in the architectural industry. Titanium- and Zirconium-based systems have successfully replaced Chrome(VI) in the majority of the world, but compared to Chrome(VI)-systems, Chrome-free systems are invisible, they have much tighter operation windows and they are quickly moving towards borderline performance in respect to filiform corrosion and paint adhesion, especially in case of ageing or contamination of the bath.

SurTec 643 combines SurTec’s long-term experience in running and operating Chrome-free technologies in regions like France, Middle East or North Africa with the well-founded understanding of our technical community to improve specific characteristics of metal pre-treatment processes. The result is a product, which uses the traditional skeleton of Zirconium and Polymer, but the choice of a brand new polymer in combination with the optimal Zirconium ingredients leads to an innovative and unique product. The coating can comfortably be controlled via the bath and easily measured in the coating. In addition, it shows a significantly improved performance in respect to filiform corrosion and paint adhesion, especially when it comes to contamination and ageing effects. On top, the uniformity of the coating weight along a profile, especially in vertical lines, could be optimized.

To cut it short: SurTec 643 brings comfort and safety to Aluminium coaters to run and control a Chrome-free process.

please contact us at sales@auschem.com.au for further information.

As acid etching remains Australia’s most common pre-powdercoating surface preparation for aluminium finishers, it is important that the most up to date and efficient chemistry developments are a high priority. For volume applicators, Australian Chemicals & Coatings has developed our Alumbrite 21 Series acid etching for extruded, honed and sheet aluminium alloys.

Alumibrite 21 Series comes in various forms specific to requirements for dip tanks, horizontal spray lines and vertical lines. All products in the series have the benefits of much lower consumption than traditional chemistry, reduced operating strength, reduced load on rinse tanks (especially important for closed loop DI systems), reduced risk of chromate poisoning, inhibitors to protect stainless steel tanks and baskets and aluminium precipitation aid to reduce load on waste treatment. Alumibrite 21 Series is specifically designed for optimum probe dosing.

In summary: Alumibrite 21 Series brings efficiency from all angles and is a worthwhile consideration for your plant.

please contact us at sales@auschem.com.au for further information.

Alumibrite 21 Series

As acid etching remains Australia’s most common pre-powdercoating surface preparation for aluminium finishers, it is important that the most up to date and efficient chemistry developments are a high priority. For volume applicators, Australian Chemicals & Coatings has developed our Alumbrite 21 Series acid etching for extruded, honed and sheet aluminium alloys.

Alumibrite 21 Series comes in various forms specific to requirements for dip tanks, horizontal spray lines and vertical lines. All products in the series have the benefits of much lower consumption than traditional chemistry, reduced operating strength, reduced load on rinse tanks (especially important for closed loop DI systems), reduced risk of chromate poisoning, inhibitors to protect stainless steel tanks and baskets and aluminium precipitation aid to reduce load on waste treatment. Alumibrite 21 Series is specifically designed for optimum probe dosing.

In summary: Alumibrite 21 Series brings efficiency from all angles and is a worthwhile consideration for your plant.

please contact us at sales@auschem.com.au for further information.

SurTec 609GV

For the best multi-metal pre-treatment go no further than SurTec 609GV Zetacoat.

SurTec 609GV out performs zinc phosphate in most applications without heat or sludge. Incredibly easy to use promoting excellent protection and adhesion, whether contact time is 30 seconds or 5 mins you will not see delamination

There is no other product on the Australian market with such performance and versatility. This ROHS compliant chemistry is especially robust against flash rusting and is suitable as multi-metal passivation prior to painting steel, aluminium, HDG, EG, zinc and zinc die cast.

please contact us at sales@auschem.com.au for further information.

Alumifix BN

As chromate baths age they can slow down and stop working. Many of our competitors will advise that a very costly bath dump is necessary, however, this may not be the case.

Auschem is the only company in Australia offering an in situ fix.

Alumifix BN was developed to counter the sulphate drag in & extend the bath life of older chromate conversion baths. Particularly where the number of rinse tanks are limited & water flow rates are not removing the sulphate levels in these rinse tanks. Consequently the sulphate ends up in the chromate conversion bath slowly reducing the bath quality.

please contact us at sales@auschem.com.au for further information.

Closed Loop DI

Using a Closed Loop DI system? Reduce the load on it and dramatically improve time between regenerations with SurTec 650, up to 3 x the run time between regenerations. Along with its bare metal protection benefits it has the longest bath life of any chrome 6 free product on the Australian market, and does not require a bleed.

Chrome 6 is an oxidising anion. The resins in these systems suffer from reduce lifespan in the presences of oxidisers making resin replace (very high cost) more frequent. SurTec 650 does not contain oxidisers or anions means extended lifespan of resin and reduced load on resins.

Remove carcinogenic chrome 6 from your plant whilst improving costs on bath life, consumption, regeneration/waste treatment costs. All this and maintain comparable performance to chrome 6 with an easier to use, non DG, product.

All of the above adds up to large cost savings, short term and long term.

please contact us at sales@auschem.com.au for further information.

ALuminium Pretreatment Types and Performance Levels

As yellow (gold) chromate is becoming harder and harder to use safely and dispose of waste, it is important to remember that chrome free is not the only choice.

With Surtec’s range of safe, non toxic, ROHS approved chrome III choices it is not essential to go all the way from chrome VI to chrome free. Chrome III offers superior protection, wider coating parameters and serious ease of use benefits. Chrome III has become the chemistry of choice for aerospace bare metal protection, a function that chrome free cannot offer.

please contact us at sales@auschem.com.au for more info on your Qualicoat approved chrome free and chrome III choices.

Alugold SCR

Introducing ALUGOLD SCR, new to SurTec from the Italtechno range. ALUGOLD SCR is a Qualicoat approved non chrome with colour! As seen above.

ALUGOLD SCR is a coloured chrome-free liquid process, based on a perfect balance of inorganic acid salts. In contact with aluminium it reacts to form a coloured passivation layer of metallic complexes particularly suitable for aluminium treatment before powder coating. The product is chrome-free. ALUGOLD SCR may be applied by spray, cascade or dipping.

Australian Chemicals & Coatings are now able to offer to the Australian and New Zealand market a product that has the health benefits of non chrome with the visual benefits of chrome 6.

With SurTec’s acquisition of Italtechno we are now able to combine Italtechno’s aluminium expertise with SurTec’s facilitlies and Australian Chemicals & Coatings local support.

please contact us at sales@auschem.com.au for further information.